What Does Anything Cost?

Before launching into the issue of cost, we want to remind everyone of the various “costs” contexts. There are procurement costs, material costs, construction costs, labor costs, operational costs, maintenance costs, and life cycle costs. Then there are the ancillary opportunity costs, economic stimulus costs, environmental costs, congestion costs, delay costs, security costs and costs in human lives from system failures.

In 2002, a Washington Post editor was approached about running an opinion piece on maglev deployment. Her knee-jerk response was, “Everybody knows about maglev – it costs too much.” The truth was that she did not empirically know the facts and was not referencing any verifiable data. Yet, that did not stop her from venturing her opinion about maglev’s cost. She was simply parroting what someone else had told her. It can also be seen in her statement that she obviously assumed that “maglev” was just one technology, when in actuality magnetic levitation is achieved through various technical approaches. Unfortunately, her bias led her to reject the piece, thus perpetuating the conventional wisdom.

If you want to see how large projects such as a maglev system get funded, be sure to visit the video section: Funding Maglev Infrastructure. You will see a brilliant financial explanation as to how projects get funded and where the money is hiding.

What Does Maglev Cost?

Believe it or not, initial capital costs are now about the same or even less than traditional HMR (High-Maintenance Rail) infrastructure; especially when including the costs for signaling, unsightly catenary (power lines), tracks and switches.

The German HSM costs are now down to ~$30-40 million per mile for a dual-track high-speed maglev guideway complete with hidden power lines (no catenary needed), transformers, and operating system (the automatic OS eliminates the need for signaling). This estimate, of course, assumes average topography. However, the more difficult the terrain, the more a maglev system gains a cost advantage over HMR because the elevated guideway design does not require a fully graded right of way limited to a 3-4% incline.

In addition, what makes all maglev systems financially attractive are the dramatically lower maintenance costs, regardless of operational speeds. The executive director of NAMTI, Kevin Coates, refers to this as maglev having no “speed/maintenance penalty.”

With HMR at high-speeds, maintenance costs increase exponentially as the speed increases. Due to their frictionless propulsion, cruising and braking, HSMs have a huge maintenance cost advantage that enables all potential operators of maglev systems to realize a faster return on investment. HSM‘s ability to operate in all weather conditions does not hurt an operator’s bottom line, either. Low operations and maintenance also allows fares to be kept low and ensures ultra-high levels of system reliability, both of which will attract frequent repeat ridership. One need only look at the worsening operational condition of the Washington Metro system to understand the nature of this argument. Incidentally, the top speed of the Metro (~60 mph) is literally a fraction of the German HSM (1/6) and the Japanese HSM (1/7), both of which have lower maintenance requirements than the much slower Metro system.

It is also important to note that a HSM‘s greater (frictionless) grade climbing ability and turn radius provide greater flexibility in choosing a route alignment with the potential of lowering deployment costs further.

The persistent ignorance regarding maglev costs is easy to understand when one considers that no one can grapple with the issue of cost until they are thoroughly familiar with the technology. Since maglev is not traditional rail technology, it is not well understood by traditional rail consultants and officials from the Federal Railroad Administration, especially since the FRA eliminated the position of Chief Maglev Scientist in 2005.

To make matters worse, there are documented examples in the United States of competing railroad interests spreading outrageously inflated numbers regarding maglev deployment that are often repeated by politicians, pundits and the media without anyone bothering to verify those unsubstantiated numbers.

To be sure, all maglev systems do not cost the same to build, operate and maintain. Typically, the higher the operating speeds, the higher the operational costs (it takes more energy to go faster) and the higher the initial capital costs for a more robust infrastructure (higher speeds create higher stress). However, maintenance costs remain at a relatively low level regardless of speed – that is the huge advantage of maglev transport technology.

Comparing HMR Infrastructure Costs to Maglev

Click on each of the three images below for a dose of engineering and financial reality. It should be quite apparent to even the untrained eye that HMR infrastructure is not small or cheap and that HSM infrastructure is not significantly different. Certainly, the preposterous claims that maglev infrastructure costs 6 to 7 times more than HMR are obviously not true, as can be logically ascertained from these slides.

| Material Mass Comparison HMR vs. Maglev | Support Piers & Geotechnical Requirements | Guideway Rigidity To Defy Unwanted Deflection |

|---|---|---|

Now click on the chart below from the Thyssen-Krupp company out of Germany to see their chart for a materials mass (i.e., cost) comparison between HMR and HSM in various configurations. The next chart is from the Max Boegl Company and shows the improvements that have been made over the last ten years in guideway cost reduction and longevity. The last chart is from Transrapid from over ten years ago. There have been two generations of guideway development since this chart was created with dramatic cost improvements realized. The chart was comparing steel guideways to HSR infrastructure and does not reflect the cost and life cycle advantages of the new all-concrete guideways from Max Boegl . It should be noted that Max Boegl is the only engineering firm that has experience designing and building both high-speed rail slab track and high-speed maglev guideways.

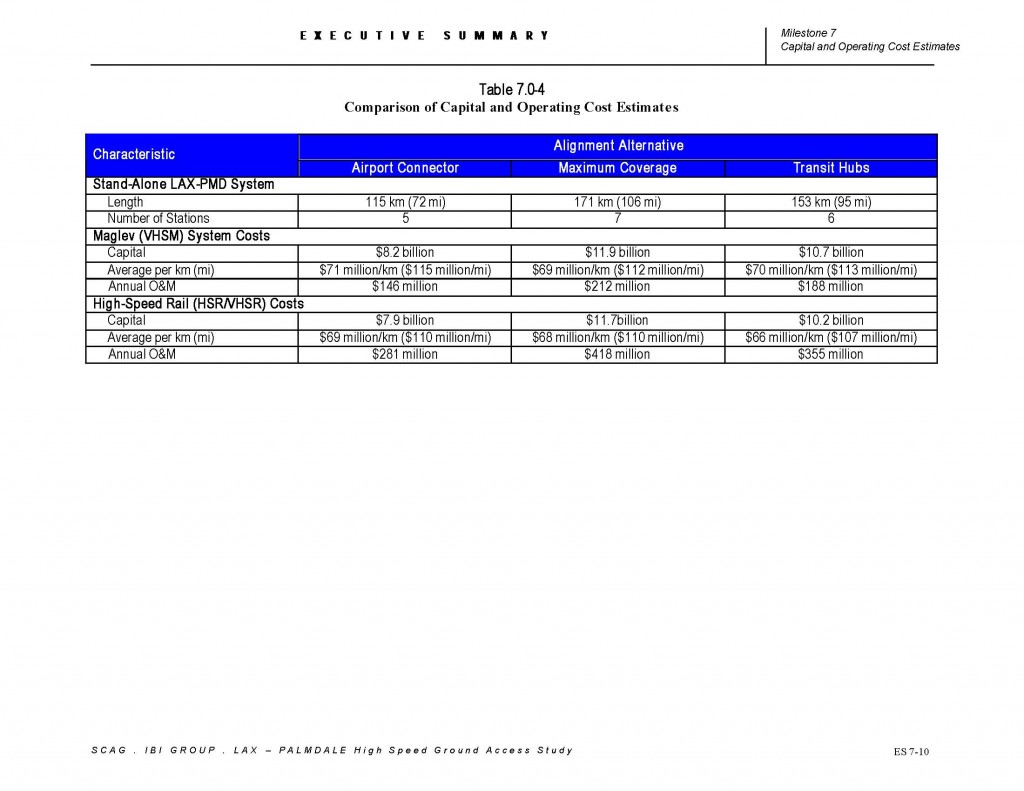

The last piece of compelling evidence to support the use of HSM over fast HMR is a study done nearly ten years ago by the IBI Group for the Southern California Association of Governments. In this study, which is based upon the old steel guideway paradigm (i.e., more costly), IBI clearly shows that the dramatically lower O&M costs for maglev and its infrastructure’s more flexible design requirements allow for cost recovery at a much faster rate. Be sure to look at the last page of this executive summary for the cost comparison chart. An image of it is included below: